Application

As part of an iron ore crushing circuit, any particle over 12mm was required to return for further processing. The entire system was to be designed so that at certain times, the entire screening section can be bypassed.

Dust suppression and removal was a requirement for this project. There was also a requirement for this unit to be serviced by only a single operator.

Solution

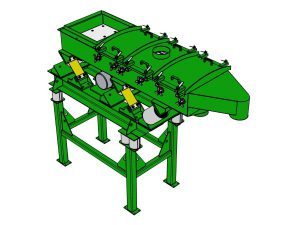

A woven wire mesh was chosen as the screening media. This was tensioned using a traditional side clamping system. In this application, the clamps were tightened by bolts instead of hand knobs so that it could be changed by a single person without tools.

Covers were designed so that their weight did not exceed 10kg as to allow a single operator to remove them. They are attached to the trough by a simple quick release system.

Bisalloy liners are located on the bottom of the trough and at the impact deck.

A 200mm extraction spigot is installed on one lid so that all dust can be withdrawn via exhaust.

| Vibroflow Reference | J206 |

| Industry | Mining |

| Product | Iron Ore |

| Equipment Type | Vibrating Screen |

| Drive | Sub Resonant |

| Liner | Bisalloy |

| Support | Steel Coil Spring |

| Construction | Mild Steel |

| Motor Qty | 2 |

| Length (mm) | 2929 |

| Width (mm) | 894 |

| Height (mm) | 2190 |

| Capacity (tph) | 3 |