Application

Due to space restrictions in a local cement plant, Vibroflow had to custom design two vibratory feeders that would allow the client to precicely feed clinker onto a belt conveyor.

Solution

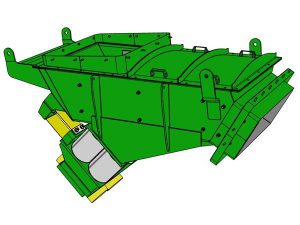

Due to the fine feed rate control required, the best drive system was sub resonant. With the addition of a counter mass, this made fitting difficult. A redesigned ‘concentrated’ drive was installed to make the unit fit into the required space envelope.

The use of heavy CC1500 wear liners also limited the drive choices to sub resonant.

These units are compact and dust tight with rubber seals on the inlet and discharge. The trough also incorporates removable covers.

Both feeders are suspended via ropes and steel coil isolating springs.

Two 0.35kw motors excite these feeders to achieve a feed rate of 150tph of clinker cement.

| Vibroflow Reference | J196 |

| Industry | Quarry / Mineral Processing |

| Product | Cement |

| Equipment Type | Vibrating Feeder |

| Drive | Sub Resonant |

| Liner | CC 1500 |

| Support | Steel Coil Spring |

| Construction | Mild Steel |

| Motor Qty | 2 |

| Length (mm) | 2000 |

| Width (mm) | 942 |

| Height (mm) | 1502 |

| Capacity (tph) | 150 |