Application

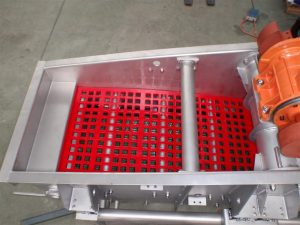

Due to the success of the stainless slurry screen, FMG research had requested a second double deck unit to further separate iron ore particles.

The client wanted 32mm aperture top deck and 8mm aperture on the bottom deck. The 8mm became an issue due to the high percentage of near size particles which would make cleaning a necessity. The client also wanted a stainless steel trough so as to avoid any contamination.

Solution

Vibroflow suggested a screen design that would allow the top deck to be removed with a single operator very quickly. This involved the design of a ratcheting tensioning system that was secured at only one point. The hooks on the screening media had to be moved from sides to back and front in order for this new system to operate properly.

The result is a simple and reliable double deck vibratory screen which can be maintained by a single operator who will need access to the bottom deck frequently.

| Vibroflow Reference | J179 |

| Industry | Mining |

| Product | Iron Ore |

| Equipment Type | Vibrating Screen |

| Drive | Direct Drive |

| Liner | |

| Support | Oscillating Mount |

| Construction | Stainless Steel |

| Motor Qty | 2 |

| Length (mm) | 1934 |

| Width (mm) | 916 |

| Height (mm) | 2279 |

| Capacity (tph) | 5 |