Application

An Australian battery recycler, adopted a new sustainability target to make sure all products that come into their yards leave as single material streams. To help achieve this target, the company invested in two sub resonant vibratory screens to size shredded Lithium Ion batteries. Since the batteries have gone through a shredding and granulating process, a large portion of the batteries are now in the form of dust.

Solution

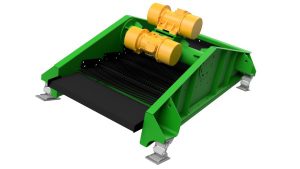

Vibroflow offered two mild steel sub resonant screens. Due to the fine dust-like nature of the product to be recovered, the units were supplied with 0.5mm aperture woven wire mesh initially. A rubber ball deck system was also installed directly below the woven wire mesh, this provides for a constant cleaning of the screening surface as the vibration of the screen causes the rubber balls to bounce uncontrollably in all different directions thus hitting almost every region of the screening surface and thus shooting out the particles that get pegged in the fine mesh screen.

Features of this screen include:

- Steel coil springs as the isolating supports.

- Over end discharge chute for oversize.

- Discharge chute for under size material.

- 0.5mm aperture woven wire mesh with rubber ball deck system.

- Two out of balance vibratory motors.

- Steel covers with dust extraction tubes and product inlet chute.

| Vibroflow Reference | J266 |

| Industry | Recycling |

| Product | Lithium Ion Batteries |

| Equipment Type | Vibrating Screen |

| Drive | Sub Resonant |

| Liner | |

| Support | Steel Coil Spring |

| Construction | Mild Steel |

| Motor Qty | 2 |

| Length (mm) | 4724 |

| Width (mm) | 848 |

| Height (mm) | 1257 |

| Capacity (tph) | 20 |