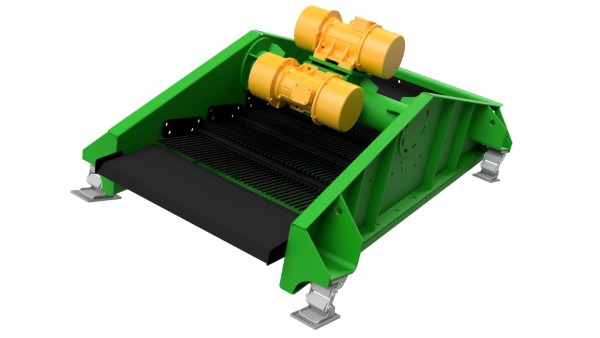

Application

Brisbane Cullet, an Australian glass packaging manufacturer, needed a vibratory finger deck screen to process glass bottlenecks. The product was to be fed and discharged by a conveyor on either side of the screen at a rate of 40T/hr.

Solution

Broken glass coupled with a feed rate of 40T/hr is extremely abrasive. In order to extend the longevity of this unit, Vibroflow offered steel finger bar decks for the screening media and ceramic liners on all material contact surface areas. Vibroflow exploited the round profile of the finger bars to introduce rotation in the material flow which complemented the long and round nature of the bottlenecks to be processed. The decks were also arranged in a cascade to allow material to tumble.

Features of this sizing screen included:

- Rosta supports for the oscillating mounts.

- Finger bar decks for screening media.

- Ceramic liners on all material contact surface areas.

- Inlet impact deck.

- Open drop discharge chute for undersize material.

- Front discharge chute for oversize material.

| Vibroflow Reference | J290-2 |

| Industry | Recycling |

| Product | Mixed Glass |

| Equipment Type | Vibrating Screen |

| Drive | Direct Drive |

| Liner | Ceramic |

| Support | Oscillating Mount |

| Construction | Mild Steel |

| Motor Qty | 2 |

| Length (mm) | 2309 |

| Width (mm) | 1352 |

| Height (mm) | 1146 |

| Capacity (tph) | 40 |