Application

Supplied together with the long sealed conveyor, this screen also had severe sealing requirements due to the toxic nature of sodium cyanide.

Inspection and cleaning of the unit was a priority for the client in this application.

Solution

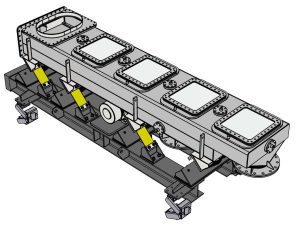

A sub resonant vibratory screen was supplied that was built together from two pressed halves.

The unit was tested under mains pressure to see if there were any leaks present in the joins.

Four inspection windows were installed on the roof of the unit as well as six inlets for spray cleaning systems.

Oscillating mounts were installed to minimise vibration passing to the plant floor.

This unit relies on a single low 0.75kw vibratory motor for operation.

| Vibroflow Reference | J199-1 |

| Industry | Chemical / Fertiliser / Salt |

| Product | Cyanide |

| Equipment Type | Vibrating Screen |

| Drive | Sub Resonant |

| Liner | |

| Support | Oscillating Mount |

| Construction | Stainless Steel |

| Motor Qty | 1 |

| Length (mm) | 3986 |

| Width (mm) | 1229 |

| Height (mm) | 1293 |

| Capacity (tph) | 10 |