Application

As part of ongoing research and development, a large iron ore miner has request a 316 stainless steel slurry screen for material testing. In this application, sands needed to be screened out from natural fines from an iron ore pilot scale scrubber.

Solution

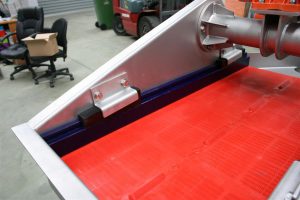

The unit offered was designed to process 1.5tph of slurry and fit standardised Screenex type panels. A frame mounted pump hopper was integrated into the design to remove undersize screened slurry.

Overhead motors were installed for unit stability and ease of access. The central motor mount tube can be adjusted 5 degrees in order to orient the vibration more vertically if it is required.

Oscillating mounts were used to make the whole frame and screen one single piece of equipment for transport purposes.

This is an example of a standard design directly driven vibratory screen.

| Vibroflow Reference | J175 |

| Industry | Mining |

| Product | Iron Ore |

| Equipment Type | Vibrating Screen |

| Drive | Direct Drive |

| Liner | |

| Support | Oscillating Mount |

| Construction | Stainless Steel |

| Motor Qty | 2 |

| Length (mm) | 1589 |

| Width (mm) | 848 |

| Height (mm) | 1431 |

| Capacity (tph) | 1.5 |