Application

Product from two output chutes needed to be mixed and discharged at a single location.

Vertical space was limited so a compact design was required.

The floor is cleaned often and the equipment should provide a minimal footprint.

Solution

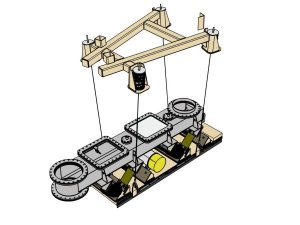

Two twin mass vibratory conveyors were designed to fit in this envelope. Due to space restrictions, both units are of a slightly different design but are very similar.

A hanger system is installed to suspend these units to an overhead frame. This allows free and easy cleaning of the floor underneath.

One unit is elevated slightly relative to the other with material passing through both conveyors.

The trough is made in a similar fashion to the long sealed conveyor and sealed chemical screen

Inspection windows and water spray points are integrated into the trough structure.

| Vibroflow Reference | J199-3-1 |

| Industry | Chemical / Fertiliser / Salt |

| Product | Cyanide |

| Equipment Type | Vibrating Conveyor |

| Drive | Sub Resonant |

| Liner | |

| Support | Steel Coil Spring |

| Construction | Stainless Steel |

| Motor Qty | 1 |

| Length (mm) | 2700 |

| Width (mm) | 600 |

| Height (mm) | 1030 |

| Capacity (tph) | 3.4 |